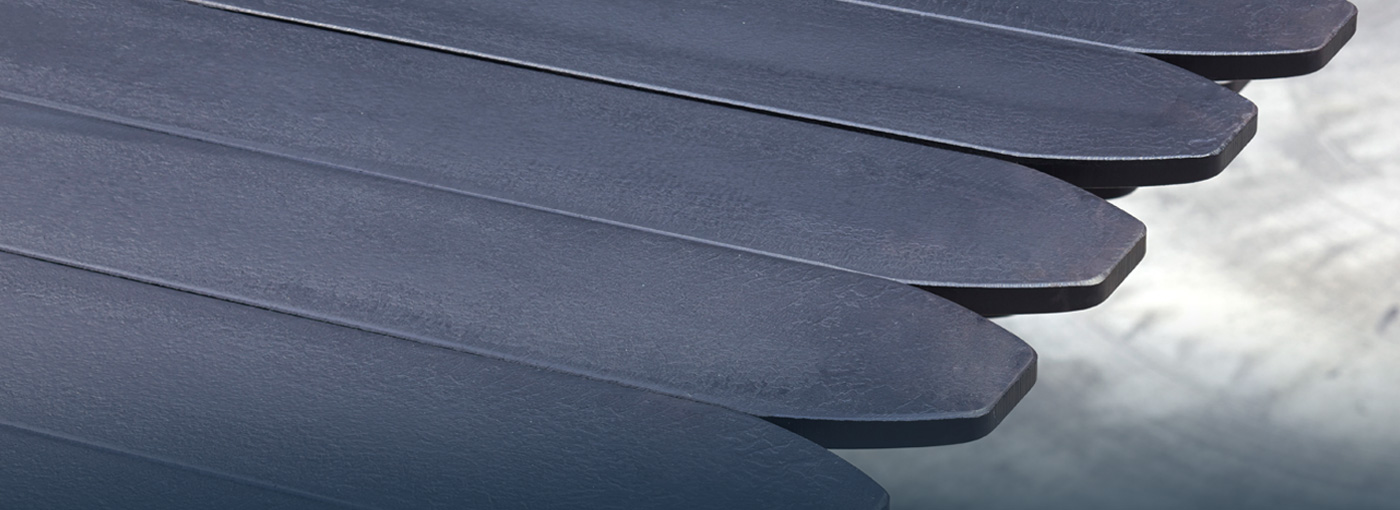

Forks for lift trucks

Earth moving machinery and agricultural machinery

Quality forks, accurate and efficient service and qualified technical support are the strengths that have allowed Delta Effe to be recognized as a well-established and successful company in the international market.

The expertise developed in steel hot working by the Leali family in over two centuries and their determination to implement, as well as diversify, the company's productive capacity have resulted in the installation of an advanced plant for the forging of special steel and non-ferrous alloys. This has allowed Delta Effe to produce forgings of the highest quality, but also to complete the range of manufactured forks by expanding the supply of special sections for small and large capacities.

Delta Effe's decisive factor for the achievement of the company's objectives has always been its constant effort to work seriously and competently in order to establish a collaborative relation with its suppliers and customers.

Today Delta Effe is a leading manufacturer of all types of forks: standard for lift trucks, earthmoving, forged and special, for all industrial sectors, entirely made in the company headquarters and in compliance with current regulations and strict quality protocols. The company also stands out for the design consultancy and technical assistance service offered, for the punctuality and promptness of the delivery, as well as for the wide variety of forks always in stock.

Google maps

Google maps